Delving into the Realm of 4-Bar MAP Sensors: A Comprehensive Guide

Related Articles: Delving into the Realm of 4-Bar MAP Sensors: A Comprehensive Guide

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to Delving into the Realm of 4-Bar MAP Sensors: A Comprehensive Guide. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Delving into the Realm of 4-Bar MAP Sensors: A Comprehensive Guide

The intricate dance of air and fuel within an internal combustion engine relies on precise measurements and control. A crucial component in this intricate ballet is the Manifold Absolute Pressure (MAP) sensor, a device that plays a vital role in determining the engine’s load and fueling requirements. While various types of MAP sensors exist, the 4-bar MAP sensor stands out as a popular choice in performance and high-performance automotive applications.

Understanding the Essence of a MAP Sensor

At its core, a MAP sensor is a transducer that converts the absolute pressure within the intake manifold into a measurable electrical signal. This signal, interpreted by the engine control unit (ECU), provides valuable information about the engine’s load, allowing for precise fuel delivery and ignition timing adjustments.

The Significance of 4-Bar MAP Sensors

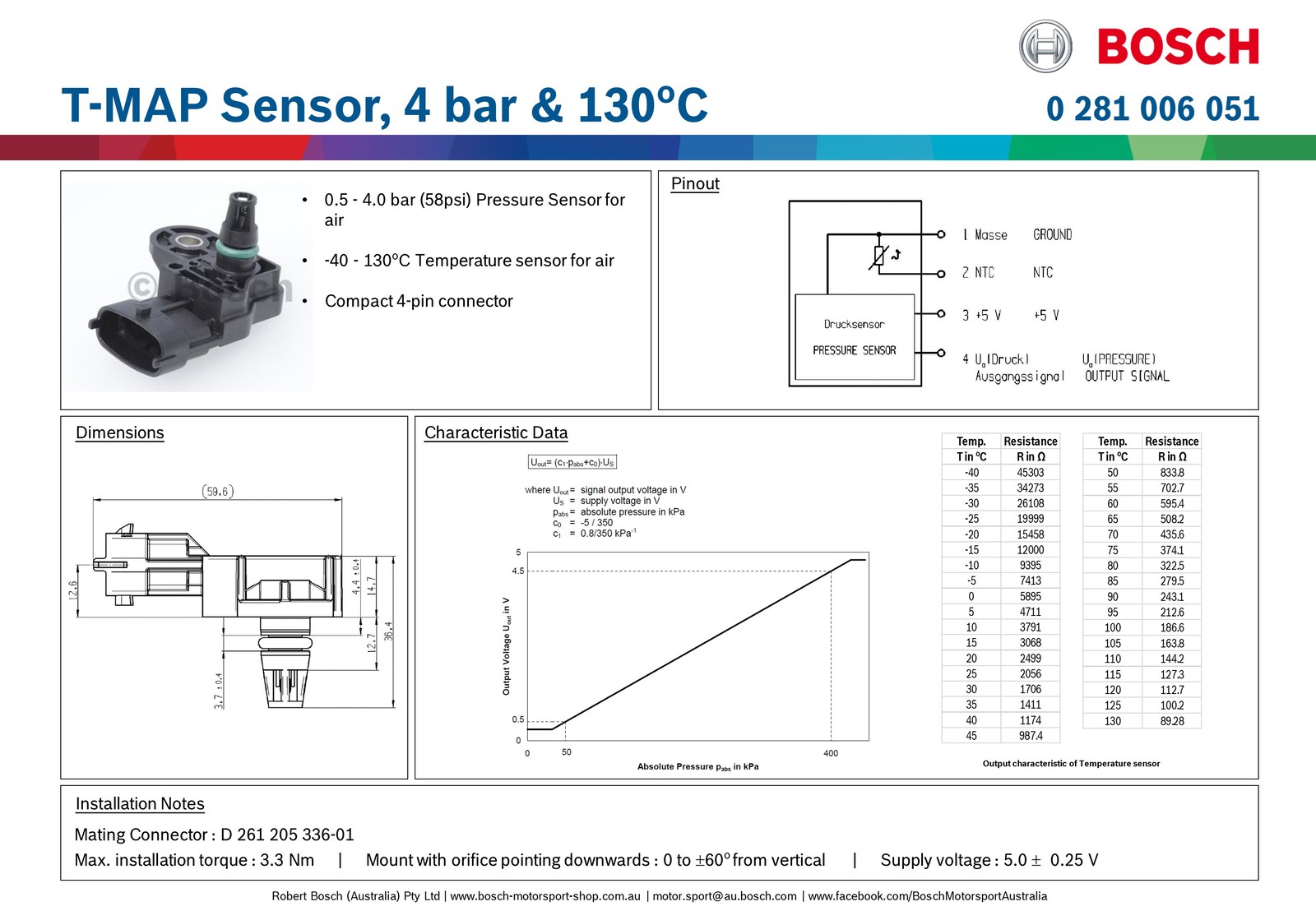

The "4-bar" designation refers to the sensor’s ability to measure pressure up to 4 bar (58 psi). This high pressure range makes 4-bar MAP sensors particularly well-suited for applications where engine boost pressures are significant, such as turbocharged or supercharged vehicles.

The Mechanics of a 4-Bar MAP Sensor

A typical 4-bar MAP sensor comprises a diaphragm, a sensing element, and an electronic circuit. The diaphragm, made of a flexible material, is exposed to the intake manifold pressure. As pressure changes, the diaphragm flexes, altering the position of the sensing element. This change in position is converted into an electrical signal by the electronic circuit, which is then transmitted to the ECU.

Benefits of Employing a 4-Bar MAP Sensor

The use of a 4-bar MAP sensor in high-performance applications brings several advantages:

- Enhanced Performance: The ability to accurately measure high boost pressures allows for more precise fuel delivery and ignition timing adjustments, leading to improved engine performance and power output.

- Improved Fuel Efficiency: By providing the ECU with accurate load information, a 4-bar MAP sensor facilitates optimal fuel consumption, potentially improving fuel efficiency.

- Reduced Emissions: Precise fuel management contributes to lower emissions, ensuring compliance with environmental regulations.

- Increased Durability: 4-bar MAP sensors are designed to withstand higher pressures, offering enhanced durability in demanding environments.

Considerations When Choosing a 4-Bar MAP Sensor

While the advantages of a 4-bar MAP sensor are clear, several factors should be considered during selection:

- Compatibility: Ensure the chosen sensor is compatible with the specific ECU and engine application.

- Pressure Range: Select a sensor with a pressure range sufficient for the intended application.

- Accuracy: Opt for a sensor with high accuracy to ensure precise pressure readings.

- Reliability: Choose a sensor from a reputable manufacturer known for reliability and longevity.

Frequently Asked Questions (FAQs) about 4-Bar MAP Sensors

Q: How do I know if my vehicle requires a 4-bar MAP sensor?

A: If your vehicle is turbocharged or supercharged, or if you plan to modify your engine to increase boost pressure, a 4-bar MAP sensor is likely necessary.

Q: Can I replace a standard MAP sensor with a 4-bar MAP sensor?

A: Replacing a standard MAP sensor with a 4-bar MAP sensor without proper ECU calibration can lead to inaccurate readings and potential engine damage.

Q: What are the signs of a faulty 4-bar MAP sensor?

A: Symptoms of a faulty 4-bar MAP sensor include poor engine performance, rough idling, increased fuel consumption, and check engine light illumination.

Q: How do I calibrate a 4-bar MAP sensor?

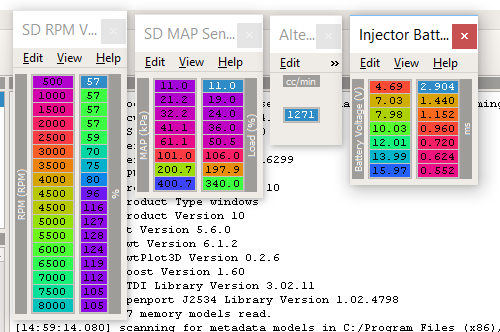

A: Calibration of a 4-bar MAP sensor is typically performed through ECU tuning software, requiring specialized knowledge and tools.

Tips for Maximizing Performance with a 4-Bar MAP Sensor

- Proper Installation: Ensure the sensor is correctly installed and securely connected to the intake manifold and ECU.

- Regular Inspection: Periodically inspect the sensor for signs of damage or debris accumulation.

- ECU Calibration: Calibrate the ECU to match the specific characteristics of the 4-bar MAP sensor for optimal performance.

Conclusion

The 4-bar MAP sensor plays a crucial role in optimizing performance and efficiency in high-performance automotive applications. By accurately measuring intake manifold pressure, it enables precise fuel delivery and ignition timing adjustments, leading to increased power output, improved fuel economy, and reduced emissions. When choosing a 4-bar MAP sensor, consider compatibility, pressure range, accuracy, and reliability to ensure optimal performance and longevity. With careful selection and proper implementation, a 4-bar MAP sensor can significantly enhance the overall performance and driving experience of high-performance vehicles.

Closure

Thus, we hope this article has provided valuable insights into Delving into the Realm of 4-Bar MAP Sensors: A Comprehensive Guide. We appreciate your attention to our article. See you in our next article!